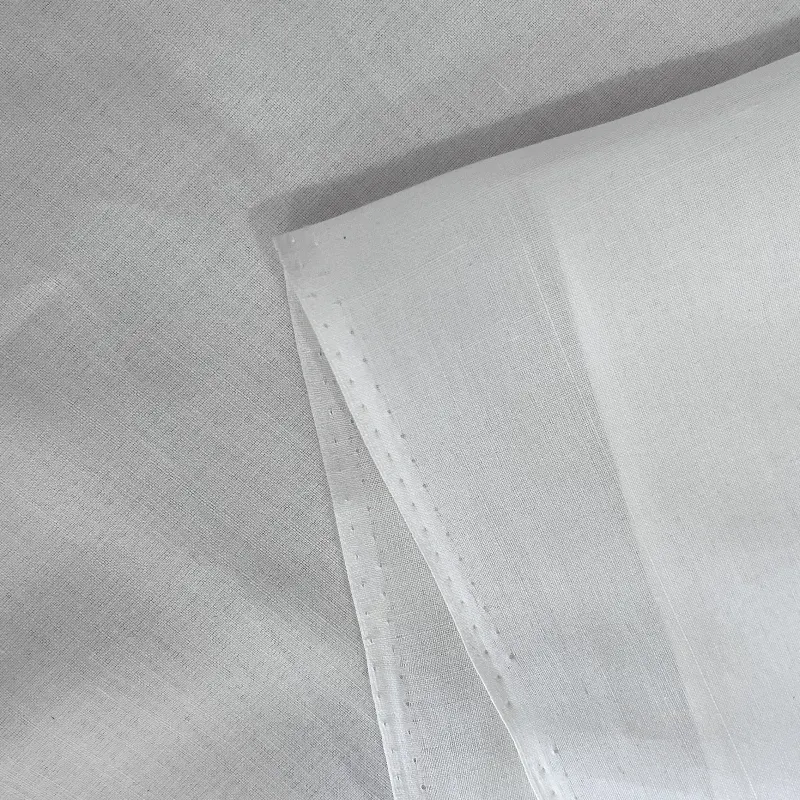

polyester voile white fabric

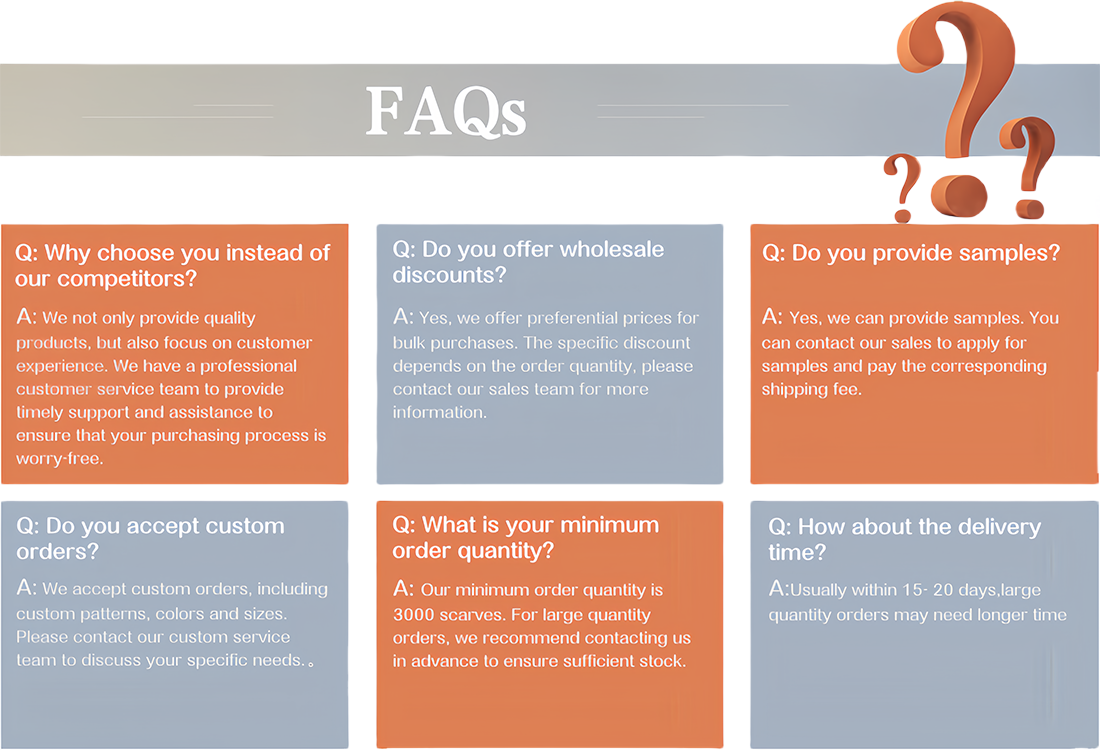

Descripsion

Half Bleach means original white, that is, fabric that only undergoes pre-processing and no dyeing treatment is usually called semi-bleached fabric (Preapre for printing or prepare for dyeing.) In other words, semi-bleached cloth is a semi-finished fabric that needs to undergo subsequent processing. , generally those who buy this kind of products go to foreign countries for printing or dyeing. To put it bluntly, semi-bleached fabric is a semi-finished product that can be dyed directly. The rest of the creation can be based on current fashion colors and the preferences of the textile factory.

.

The professional name for white fabric is pfp/pfd fabric.

The English abbreviation of semi-bleached fabric that has been treated before dyeing is PFD, and its full name is prepared for dyeing.

The English abbreviation of semi-bleached fabric that has been processed before printing is PFP, and its full name is prepared for printing.

1. Dyeing and finishing process:

Jinlai produces semi-bleached fabrics including 32S, 40S, 45S, 50S, 60S, 80S, as well as ring spinning 1250 twist, 1650 twist, 1750 twist, 1850 twist, vortex spinning, siro spinning, and jacquard fabric. There are also different widths and different weights to meet different customer needs.

2. Finished product process and application

The semi-bleached fabric after processing the voile gauze fabric can "show off its talents". You can take it to a printing and dyeing factory to make a variety of beautiful prints and fashionable colors. You can also take it to an embroidery factory to make embroidery with various techniques. You can also go to a sand washing factory to do retro sand washing, or make it into foam. The effect (puff sleeves), and finally, these finished fabrics will be flowed to hijab companies and made into various beautiful hijabs.

If you need a large amount of polyester voile white fabric, please contact us, we can customize the width, density, gram weight, and handfeel.