Ring spinning, air spinning, siro spinning, compact spinning... Inventory of various spinning methods

Ring spinning, air spinning, siro spinning, compact spinning... Inventory of various spinning methods

1. Ring spinning

Ring spinning is the most widely used and most common spinning method in the current market. Ring spinning refers to the fiber strips after the sliver or roving is drawn and introduced through the ring wire ring. The winding speed of the bobbin is faster than that of the wire ring. The cotton yarn is twisted into fine yarn and is widely used in various short fiber spinning projects. For example, in carding, combing and blending, the wire ring is driven by the bobbin through the yarn strip to rotate around the steel collar for twisting. At the same time, the friction of the steel collar makes its speed slightly lower than that of the bobbin and is wound. The spinning speed is high, and the shape of the ring yarn is a c

onical spiral line with most of the fibers transferred inside and outside, so that the fibers are entangled and connected inside and outside in the yarn. The structure of the yarn is compact and strong, which is suitable for various products such as thread making, weaving and knitting.

2. Air spinning

Air spinning does not use spindles, but mainly relies on multiple components such as combing rollers, spinning cups, and false twist devices. The combing roller is used to grab and comb the fed cotton sliver fibers, and the centrifugal force generated by its high-speed rotation can throw out the grabbed fibers. The spinning cup is a small metal cup, and its rotation speed is more than 10 times higher than that of the combing roller. The centrifugal effect generated by this discharges the air in the cup outward; according to the principle of fluid pressure, the cotton fibers enter the airflow cup and form a fiber flow, which moves continuously along the inner wall of the cup. At this time, there is a yarn head outside the cup, which leads the fibers on the inner wall of the cup out and connects them. In addition, the drilling effect generated by the high-speed rotation of the cup with the yarn tail is like "feeding" cotton fibers while adding yarn rubbing to connect the yarn with the fibers on the inner wall of the cup, and stretching under the winding tension of the yarn tube, continuously outputting yarn, and completing the process of air-jet spinning.

Characteristics of air-jet spinning:

Air-jet spinning has the advantages of high speed, large yarn roll, wide adaptability, simple structure and no spindles, steel collars, and steel wire rings, which can double the production of fine yarn.

3. The difference between air-spinning and ring-spinning

Air-spinning and ring-spinning are one new textile technology and the other is an old spinning technology. Air-spinning is air-spinning, while ring-spinning is mechanical spinning, which is twisted by spindles, steel bells, and steel wire rings, and drafted by rollers. Air-spinning uses airflow to transport fibers, which are held and twisted by one end. Generally speaking, ring yarn has less hairiness, higher strength, and better quality. Air-spinning has a short process, more short fibers in raw materials, and the yarn is hairy, count and twist cannot be very high, and the price is also low.

In terms of yarn body structure, ring spinning is relatively compact, while air-spinning is relatively fluffy and has a rough style, which is suitable for making denim fabrics. Air-spinning yarn is generally thicker.

4. Air-jet spinning

Air-jet spinning is a new spinning method that uses high-speed rotating airflow to twist yarn into yarn. Air-jet spinning uses cotton strips for feeding, four rollers with double short rubber rings for super-large drafting, and twisting into yarn through a fixed nozzle. After the yarn is drawn out, it is wound onto the yarn tube through the yarn clearer and directly wound into a bobbin.Jet spinning can spin 30-7.4tex (20-80 English count) yarn, which is suitable for pure spinning and blending of chemical fiber and cotton. Due to the special spinning mechanism of jet spinning, the structure and performance of jet yarn are significantly different from those of ring yarn, and its products have a unique style.

Features of jet spinning and its products:

a. High spinning speed. Jet spinning uses air twisting and has no high-speed rotating parts (such as steel wire rings in ring spinning), which realizes high-speed spinning. The spinning speed can reach 120-300 meters/minute, and the output per head is equivalent to 10-15 times that of ring spinning per spindle.

b. Short process flow. Jet spinning has two fewer processes, roving and bobbin, than ring spinning, saving about 30% of the plant area. Compared with ring spinning, 90 workers are employed for 10,000 spindles, which is about 60% less, and the machine material consumption is about 30% lower than that of ring spinning, and the usual maintenance costs and maintenance workload are also reduced. c. Good product quality and unique features. The comprehensive evaluation of the quality of air-jet yarn is good. Except that the yarn strength is 5-20% lower than that of ring-spun yarn, other quality indicators are better than those of ring-spun yarn. The physical properties of air-jet yarn, such as CV value of yarn evenness, coarse and fine details and yarn defects, are better than those of ring-spun yarn. The hairiness above 3mm is less than that of ring-spun yarn. Although the yarn strength is lower, the strength unevenness is lower than that of ring-spun yarn. It is suitable for weaving on new looms such as rapier looms and air-jet looms, and can increase the production efficiency of looms by more than 2%. In addition to being similar to ring-spun yarn, the quality of air-jet spinning is also unique. The friction coefficient of air-jet yarn is large, the yarn is directional, and its friction performance is also directional. The wear resistance is better than that of ring-spun yarn, but the hand feel is harder.Air-jet spinning can also develop some special varieties of yarns, such as fancy yarn, core-spun yarn, mixed yarn, etc. by adding some devices. d. Wide variety of adaptability. Air-jet yarn can be used for both knitted products and woven products, and has a wide variety of adaptability. The more common applications are: knitted T-shirt products, the fabric surface is even and full, without skew, few stripes, few strip defects, anti-pilling, cool and breathable, and strong three-dimensional sense; bedding, using the characteristics of good and stiff air-jet yarn, can obtain the effect of even fabric surface, thick feel, crisp and good breathability; leisure products, such as: double-sided leisure wear, sportswear, etc. According to the characteristics of air-jet yarn, unique style products can also be developed. For example, the stiffness and roughness of air-jet fabrics can be used to process them into imitation linen fabrics, crepe fabrics, imitation wool products, etc.

5. Vortex Spinning

Vortex spinning is a new spinning method that uses a fixed vortex spinning tube to replace the high-speed rotating spinning cup for spinning. In a sense, vortex spinning is the real air-jet spinning. The fiber strips are fed by the cotton feeding roller, opened into single fibers by the licker-in roller, and fed into the vortex tube at high speed from the cotton conveying pipeline by the action of air flow. The vortex tube consists of a core tube and an outer tube. There are three tangential air inlets on the outer tube, and the lower end is connected to the blower. The blower continuously draws air from the tube, and the outside air enters the vortex tube along the air inlet, generating a vortex-shaped airflow. When the rotating upward airflow reaches the core tube, it merges with the fibers entering the cotton conveying pipe, and forms a condensed fiber ring along the inner wall of the vortex tube, which stably rotates around the axis of the vortex tube at high speed to twist the fibers into yarn. The yarn is continuously drawn out from the yarn guide hole by the lead-out roller and wound into a bobbin. The most important feature of vortex spinning is that it eliminates the high-speed rotating spinning components. The use of airflow twisting gets rid of the rotational inertia problem and bearing load problem caused by the high-speed twisting components (such as the spinning cup of air-spinning), and the problem of increased spinning tension due to the air ring formed by spinning (such as ring spinning).

Advantages of vortex spinning:

fast speed and high output. The spinning speed of the vortex spinning machine is 100~200m/min, and the practical speed is generally 100~160m/min. Domestically, vortex spinning machines are used to spin 6~12 count yarns, with a spinning speed of 100~140m/min and a single yield of 600~800 (kg/1000 spindles·h), which is equivalent to 4~5 times that of ring yarn; for example, 10 PF-1 vortex spinning machines (192 heads/unit) are used to spin 40-count acrylic yarn, and the output reaches 400kg/h. This is equivalent to the output of 20 BD-200 air-spinning machines (4000 heads), and the output of 40 ring spinning machines with 16320 spindles. The output of one vortex spinning head is equivalent to the output of 2.08 air-spinning heads or 8.5 ring spindles. Since vortex spinning relies on vortex twisting, the spinning speed can be further improved if research and improvement are continued.

Short process flow and high yield rate Vortex spinning is to spin fiber strips directly into cone yarn, so like other new spinning methods, the two processes of roving and winding can be omitted. Since the breakage rate of vortex spinning is very low, the return loss is small, and the completion rate is as high as more than 99%.

Strong spinning suitability and suitable for making pile products. Vortex spinning can spin fibers with a length of 38~60mm, and is suitable for pure and blended yarns of cotton fibers and chemical fibers. The yarn structure is relatively bulky, so its dyeability, slurry absorption, and air permeability are relatively good, and the yarn's anti-pilling and wear resistance are also relatively good. The yarn count range is limited to medium and low count yarns, which are suitable for making pile products. For example, 38mm long chemical fibers (acrylic, chlorofiber, viscose, etc.) are spun into 6~12 count yarns, which are woven into knitted pile products such as fleece clothes, fleece pants, scarves, cushions, sofa fabrics, furniture fabrics and small tablecloths.

Simple operation and convenient joints. Vortex spinning uses vortex tubes to make yarns. Since the vortex tubes are stationary and have no high-speed rotating parts, the joints are very convenient and simple, and no cleaning is required after the ends are broken, which improves the working environment. There are no special requirements for pre-spinning equipment and temperature and humidity. Since vortex spinning has no high-speed rotating parts, there is no high-speed bearing lubrication problem, less wear, less noise, and easy maintenance.

Production practice shows that vortex spinning also has certain limiting factors in the development process.

a. The range of suitable raw materials for vortex spinning is limited to short chemical fibers and medium and long fibers. Due to the quality of the yarn, its competitiveness in the field of fine yarn is not strong.

b. The yarn structure of vortex spinning is relatively loose, and the long segment has good uniformity, but the strength is low and unstable, which limits its development in the field of fine yarn.

c. Although vortex spinning uses air vortex to replace the rotor of air spinning, it overcomes the wear problem caused by the high-speed rotation of the rotor of air spinning and the problem of excessive bearing load, but it still cannot solve the problem of yarn arms formed by the free end yarn tail when it rotates at high speed in the vortex tube, resulting in greater centrifugal force and tension. Therefore, its spinning speed cannot have a breakthrough progress.

d. The yarn formed by vortex spinning has a loose structure and low strength due to the poor fiber straightness and too short coagulation process. Therefore, its products are limited and are only suitable for chemical fiber raw materials and products with low strength requirements such as coarse knitting yarn or thick pile yarn, or core-spun yarn with filament as the yarn core. Nevertheless, vortex spinning, which also feeds cotton strips to directly form yarn, has the conditions and possibility to realize the production of fully automated continuous production lines. Since the roving machine, spinning machine and automatic winding machine are cancelled, the floor space, labor and investment are reduced, so it has its unique advantages and will further replace ring yarn and air-spun yarn in the field of knitting yarn.

Therefore, it is necessary to continue research and improvement to overcome its unfavorable factors and limitations and make it a new spinning method with characteristics.

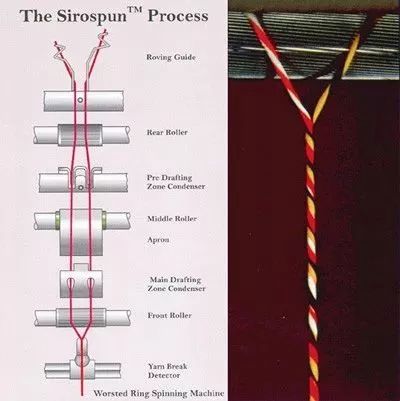

6. Siro spinning

Also known as twist spinning, domestically known as A and B yarn, it has recently been officially named Siro spinning. Siro spinning is to feed two rovings with a certain distance between them into the spinning frame. After drafting, the two single yarns are output by the front roller. Due to the transmission of twist, the single yarns have a small amount of twist. After being spliced, they are further twisted into yarns similar to ply yarns and wound on bobbins.

Siro spinning was originally designed for wool spinning. It is characterized by less hairiness, high strength, and good wear resistance, so that wool yarn can be woven into single yarns, so as to achieve the effect of thinning wool fabrics. Although Siro spinning has made great improvements in many aspects compared with similar conventional yarns, it is still a long way to go to truly achieve the weaving of wool spinning single yarns without sizing. Later, wool spinning also abandoned this method, but adopted it in blended spinning such as T/C, C.V.C, etc., because it can produce a twist effect of yarn after dyeing, and has a good feel, so it is popular. Recently, it has been used to improve the problem of hairiness, such as spinning some fibers that are prone to hairiness, such as rayon, modal, tencel, soybean fiber, and even cotton. The raw material grade used in siro yarn can be lower than that of conventional ring spinning, and its fabric has less hairiness than conventional ring spinning yarn fabric, and it feels soft, wear-resistant, and has good breathability.

Siro spinning end-break treatment Since siro spinning is fed into the spun yarn drafting zone by two strands with a certain distance, they are stretched and twisted into yarns. There is a situation that one strand of the two strands breaks and the other strand runs into single yarn, and it does not break when the spinning tension is stable, resulting in wrong yarn count. In order to ensure the spinning quality, a siro spinning single yarn breaking device needs to be installed. The breaking device can break the other strand of single yarn after one strand breaks.

7. Compact Spinning

Compact spinning is a new spinning technology that is carried out on an improved new ring spinning frame. Its spinning mechanism is mainly: a fiber coagulation zone is added in front of the traction device of the ring spinning frame, which basically eliminates the spinning twisting triangle between the front roller and the twisting point. After the fiber strands are output from the front mouth of the front roller, they first pass through the mesh leather ring on the outer jacket of the special-shaped suction tube. The strands move on the mesh leather ring. Due to the contraction and polymerization of the airflow, the strands are gathered and rotated through the suction groove of the special-shaped tube, gradually turning from a flat belt to a cylinder. The ends of the fibers are twisted into the yarn, so the yarn is very compact, the yarn appearance is smooth, and the hairiness is less. Compact spinning yarn has higher strength and less hairiness. It is least likely to produce abrasion during the weaving process.

The purpose of compact spinning is to make the fibers as parallel and close as possible before the yarn is twisted. This is an important criterion for high-quality compact spinning yarn. Making the fibers as parallel and consistent as possible before twisting is the premise of its advantages.

Advantages and Disadvantages of Compact Spinning

Advantages:

a. Before twisting, the single fibers in the yarn are fully straightened, parallel to each other, and arranged closely, so the yarn diameter becomes very small at the jaws of the twisting roller (also called the anti-twist roller, because it has the function of preventing twist transmission), so the "twisting triangle" is basically eliminated. Because the single fibers are fully straightened and parallel before twisting, no hairiness extends out of the main body of the yarn, so the yarn hairiness is very small, especially the hairiness above 3 mm is very small.

b. In the spun yarn, since each single fiber is twisted in a straight and parallel state, when the single yarn is subjected to tension, the force of each single fiber is basically the same, so the compact spinning strength is higher than that of traditional single yarn. And because the single fibers in the compact yarn are closely arranged, the mutual cohesion is large, which also helps to improve the strength of the yarn.

c. In the compact spinning process, the yarn is gathered after the drafting specified by the process is completed, so the unevenness index of the yarn is not greatly improved, but the yarn is arranged in the gathering area, and the inner and outer layer transfer of the fiber when twisting at the jaws of the twisting roller is not as strong as the traditional process, so the unevenness of the compact yarn, the coarse and fine indexes are better than the traditional yarn.

d. Due to the above characteristics of the compact yarn, it provides very good conditions for the next process. The compact yarn has less hairiness, so the pressure of sizing, singeing and other processes is reduced. When the weft yarn of the shuttleless loom is used for compact yarn, the resistance of weft insertion is greatly reduced, and the efficiency of the loom is improved.

e. Because the compact yarn fibers are closely arranged and the diameter is smaller than that of the traditional yarn of the same number, the cloth woven with the same warp and weft density has good air permeability, and the cloth surface is flat and smooth. It is an ideal yarn for high-end textiles.

Disadvantages:

a. The cost of compact spinning equipment is high, which increases the equipment investment of the spinning mill.

b. In addition to the great improvement in the hairiness index, the improvement of other yarn indicators such as yarn evenness, coarseness, and fineness is not large.

8. Comparison of Siro Spinning, Compact Spinning, and Compact Siro Spinning

a. Siro spinning is a spinning method that spins yarns similar to ply yarn structures on traditional ring spinning machines. Siro spinning technology was first applied to wool spinning and then gradually applied to cotton spinning. Siro spinning uses two rovings to feed from the bell mouth, and the two slivers are still kept separated in the front and rear drafting zones. After a certain length is output from the front jaw, they are merged and twisted by the same spindle to form a Siro yarn with double-ply structure characteristics. The synchronous twisting of Siro spinning in the same direction gives the yarn a special structure. The fibers on the surface of Siro spinning are neatly arranged, the yarn structure is compact, the hairiness is small, and the anti-pilling is good. Compared with ply yarn fabrics, Siro spinning fabrics feel soft and smooth. Siro spinning can be used for woven fabrics and knitted fabrics, and can also replace ply yarn for high-count and high-density fabrics.

b. Compact spinning technology is a new type of ring spinning technology based on traditional ring spinning. Simply put, it is a spinning technology that densifies the fibers output after the spinning machine is drafted, that is, by adding a suction device before twisting the sliver, the loose fibers are gathered and held together by the control of negative pressure, and the fibers are fully straightened in the controlled area, and the twisting triangle area on the traditional spinning machine is reduced, so that the fibers can be twisted in a parallel and tight state. Because the fibers in the sliver are evenly stressed and tightly held, the yarn structure and quality are comprehensively improved, and the hairiness, strength, dryness, wear resistance, and yarn appearance are significantly improved.

c. Compact siro spinning is a combined spinning method that combines compact spinning and siro spinning. The yarn spun by this technology combines the excellent characteristics and quality of the two spinning methods. Compared with traditional ring spinning single yarn and siro yarn, compact siro yarn has less hairiness, higher strength, and more siro spinning plying effect. It is an ideal raw material for spinning high-end fabrics and has good development prospects.