Good pre-treatment is half the success of dyeing

Good pre-treatment is half the success of dyeing

1. Batch management of raw materials (or yarn):

Therefore, before talking about pre-processing, it is important to emphasize the batch management of raw materials (or yarns). The same batches are dyed according to the same process. When changing batches, there must be a proofing and tracking program. The dyed objects are changed in batches. Finally, the process must be adjusted in a timely manner based on the proofing comparison. Good batch management and control reflects the level of a dyeing factory.

2. Desizing:

2. Desizing:

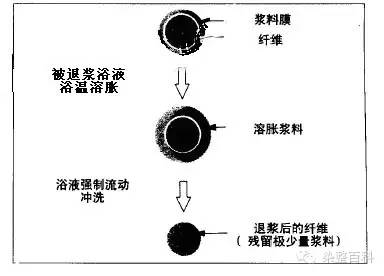

Speaking of desizing, we have to mention the three major sizing materials in the textile sizing industry: starch and derivatives, polyvinyl alcohol (PVA), and acrylic sizing. PVA has been gradually phased out due to environmental issues, and most of them are now used in combination with starch and acrylic slurry.

Insufficient desizing will affect the coloring rate of the dye during dyeing, or cause the fabric's feel to deteriorate.

3. Remove oil:

Oil removal is mainly targeted at chemical fiber fabrics (or yarns), such as polyester, nylon, etc. Incomplete oil removal will also affect the coloring of dyes and cause oil spots, stains and other problems. Degreasing is generally carried out under alkaline conditions with a degreaser and high temperature. Choosing a good degreaser will help improve the degreasing effect. Nowadays, in order to optimize the process flow, there are many degreasing and dyeing baths suitable for chemical fibers. When choosing, pay attention to the high temperature resistance and dispersion performance of the degreasing agent in the same bath.

4. Reduction:

5. Refining:

Another indicator of refining is weight loss. In principle, the higher the weight loss, the better the refining effect. However, excessive weight loss also reduces the production rate and increases the cost.

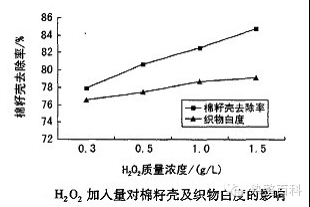

6. Bleaching:

Bleaching is also targeted at natural fibers and regenerated cellulose fibers. The one-bath treatment with scouring is commonly referred to as scouring and bleaching. The purpose of bleaching is to remove pigments to achieve the whiteness required for dyeing. Common bleaching processes include oxidative bleaching (hydrogen peroxide, sodium hypochlorite, etc.) and reduction bleaching (safety powder). The indicator of bleaching is whiteness. For sensitive and bright colors, the stability of bleaching whiteness is critical. Whiteness can be measured with the naked eye or with a whiteness meter.